We are pleased to announce that we have achieved B Corp certification! This prestigious accreditation reinforces the highest standards of social and environmental performance, public transparency, and legal accountability.

Park Lane Press has had an environmental management system since 2002, and over the years attained ISO 14001 and ISO 9001 as well as FSC certification, so B Corp compliments these achievements. Our B Corp score was 98.4 points, well over the 80 point pass mark!

B Corp assesses the company impact on workers, customers, suppliers, community, and the environment. To achieve this certification, we had to meet comprehensive performance requirements and undergo an in-depth review process conducted by B Lab, the nonprofit organisation that certifies B Corps.

It aligns with our core values of integrity, responsibility, and sustainability. It validates our efforts to run a business that prioritises more than just profits.

B Corp certification provides a trusted, third-party validation of our efforts, offering transparency to our customers, employees, and partners about our commitment to positive impact.

Joining the B Corp community connects us with like-minded businesses that are equally dedicated to driving change. This network provides opportunities for collaboration, learning, and growth.

While we are incredibly proud of our B Corp certification, we view it as a starting point, we will continue our commitment to positive impact and will continue to guide our business decisions and practices.

Within our factory, we hold onto a valuable principle: waste not, want not. It’s a mantra instilled in us from an early age, and it rings true today more than ever. Each scrap of material represents potential, and seeing it discarded hurts a little.

Today we folded 12-page sections on our MBO folder for a beautiful PUR book, we encountered a familiar scenario: the last section resulted in only an 8-page, leaving excess material. Although the white paper is being collected in a bin it’s not truly wasted.

With a bit of discipline, we’ve implemented a system to collect this clean, white waste separately. Why? Because every bit counts. Not only does it contribute to our commitment to sustainability, but it also holds economic value. Recycling companies are willing to pay a premium for this material, turning what might have been waste into pound notes.

It’s remarkable how these seemingly small actions can have a significant impact, both environmentally and economically. We’re proud to play our part in minimising waste and maximising resource efficiency. Join us in this journey towards a greener, more sustainable future. Every little effort helps!

Within the busy print room, amongst the noise of the machines there will always be a team of people hand working. Some possess an innate gift, working through tasks with ease, and seem to have been born with a natural knack for intricate work.

Then there are those like me – an office worker, pitching in to meet deadlines with a sense of urgency. I am striving to keep pace with the team, keen not to fall behind under the weight of expectation!

Is manual dexterity solely a product of innate talent, or can it be cultivated through practice and dedication? I think the truth lies somewhere in between. While some may possess inherent abilities, the rest of us can refine our skills through effort and perseverance.

Handwork becomes a rewarding aspect of working in the print room. Its an enjoyable process for a while, simply for the teamwork and obvious banter!

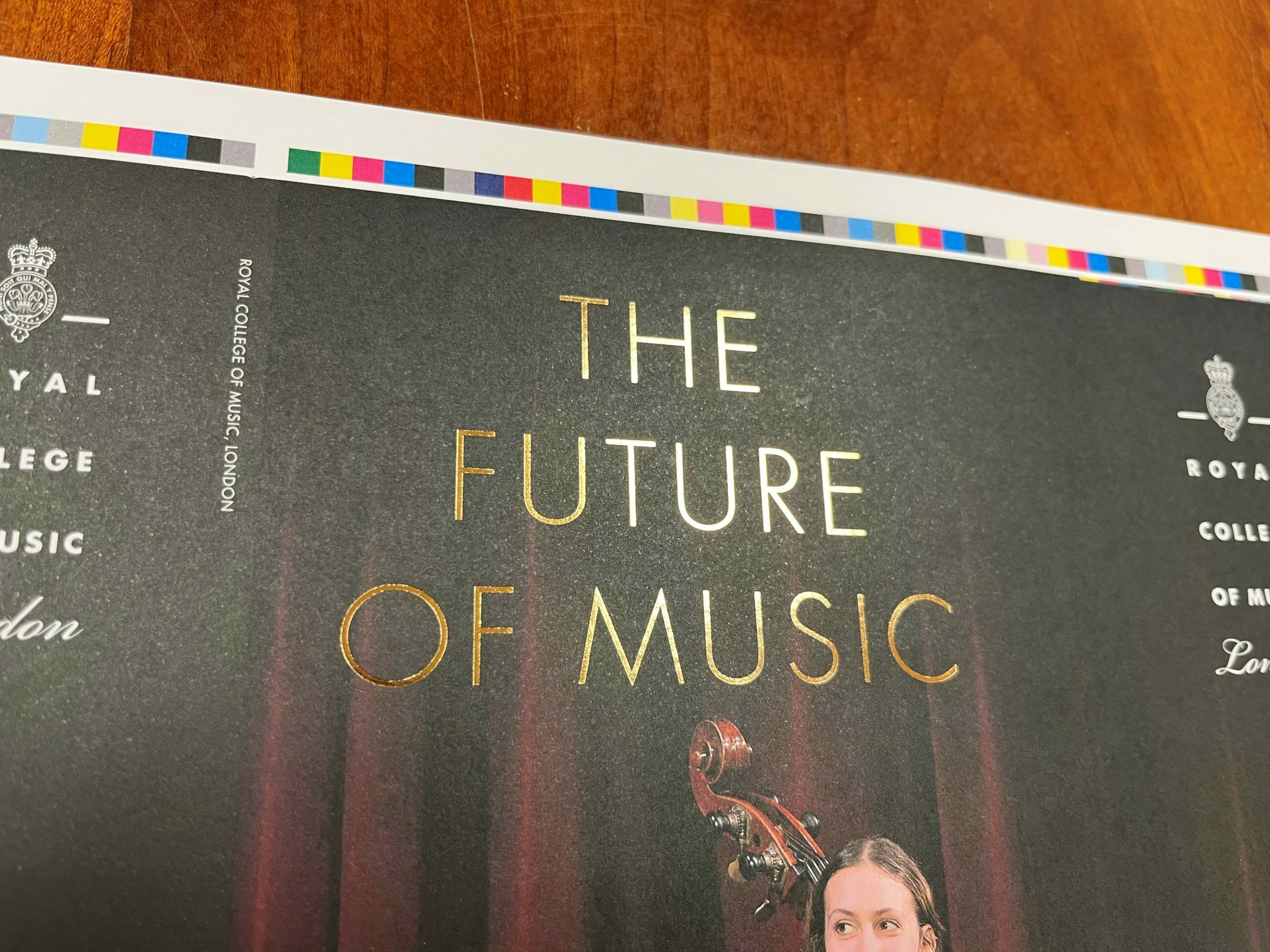

In the competitive world design, standing out is crucial. One way our customers make their book cover truly exceptional is by incorporating foiling and embossing techniques. These finishing touches not only add a touch of luxury but also create a memorable tactile experience for readers.

Foiling instantly adds a touch of sophistication to your book cover. Whether it’s metallic or coloured foil, it catches the light in a unique way, giving your design a premium look.

Embossing creates a raised effect that invites readers to touch and feel the design, adding a sensory dimension to their reading experience. Embossing can be strategically used to emphasise titles, images, or logos, and helps it to stand out on the shelf.

When foiling and embossing are combined, the result is truly spectacular. Together, these techniques create an ultra-luxurious look, that strengthens brand recognition and makes your book more memorable.

At Park Lane Press the ability to foil and emboss in house has meant that we can provide this service at a sensible price and turnaround, the machine is one of the busiest in the factory for obvious reasons!

Please contact our team and they will be more than happy to discuss the options.

Maybe its that I’m getting a little more sensitive as I get older but there is a beauty in print! I know some of our machines are hefty, noisy and sometimes a little scary, but there are many that are refined, graceful and truly impressive.

Such as the single knife trimmer, trimming the edge of the books in perfect sequence or the plate processor automatically, collecting, punching, processing plates and then finally gathering them together into sets. Its the sort of thing that you catch yourself stopping to watch – spellbound!

And the outcome? A meticulously arranged pallet, akin to a carefully wrapped gift, awaiting delivery to our valued customers.”

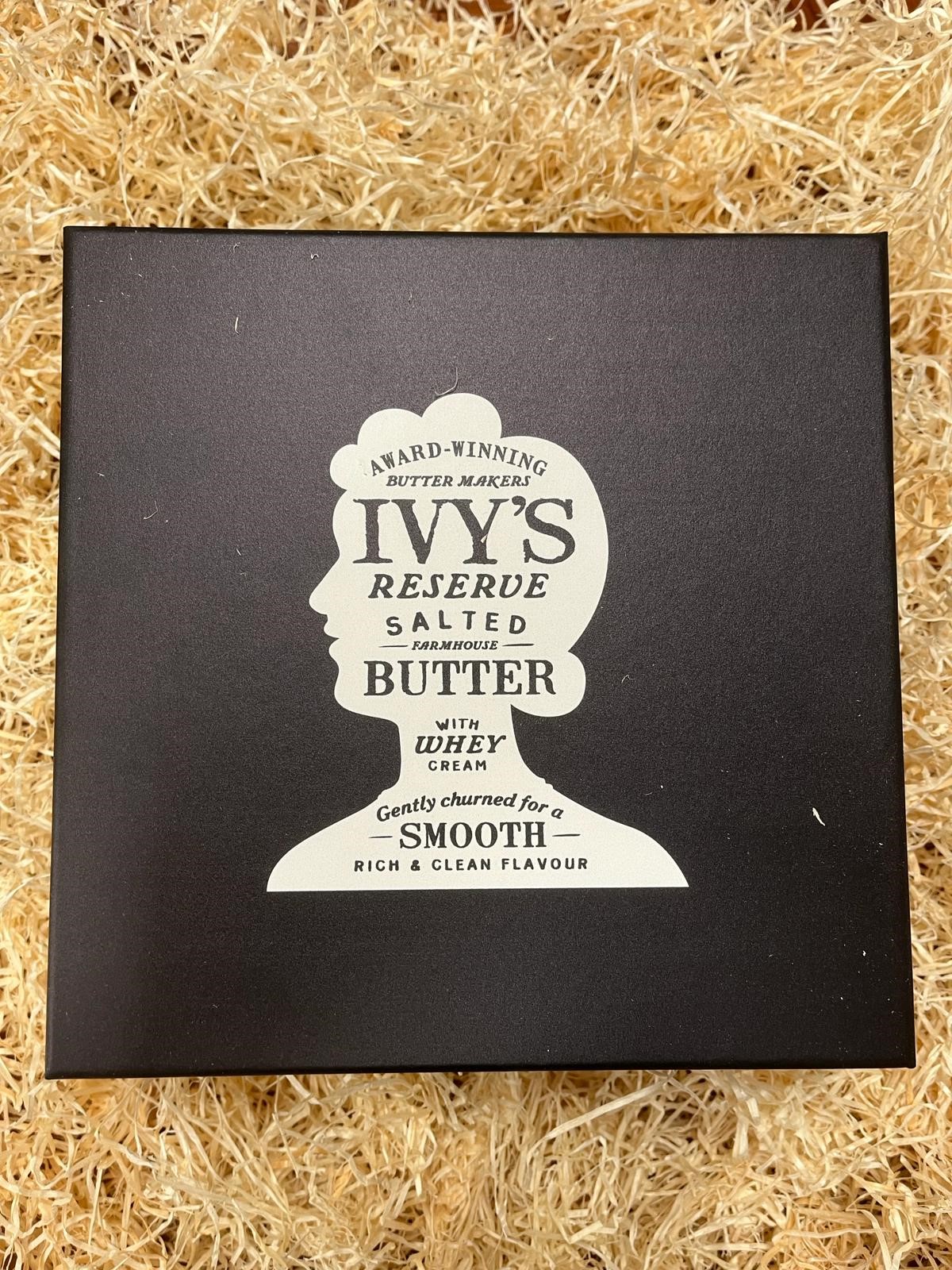

Thrilled to share the success story of our recent project with @Wyke Farms, where we showcased their exquisite Ivy’s Reserve Somerset Red cheese and Ivy’s special recipe farmhouse butter to major retailers.

We meticulously crafted a range of print items and custom-designed boxes to highlight these delectable products, capturing the attention of our target retailers. By personalising each box to the recipient, it fostered face-to-face meetings that opened doors to new opportunities for distribution.

With quality collateral and personalised print materials perfectly complementing these mouth watering offerings, it’s truly a winning combination!

Here is our latest poster image and what a beauty it is! The photographer, Julian Calverley @juliancalverley.com has collaborated with us and agreed to allow us use this fantastic image to help promote Park Lane Press.

Printed using the waterless process with a screen ruling of 300 lines per inch provides production values that are off the charts. The Waterless process allows us to produce the detail and contrast that conventional print simply struggles to achieve especially on uncoated paper using vegetable based VOC free inks.

The poster mailer was a picture of Essex & Herts Air Ambulance, unlike NHS emergency services, is a charity. The free life-saving service is provided 24/7 by helicopters and by rapid response vehicles.

Each critical care team consists of a pilot and co-pilot, a pre-hospital care doctor and a critical care paramedic.

They can be rushed to the scene with life-saving support equipment to deliver advanced clinical care, usually only available in the hospital emergency department. What a fantastic job they do!

Do you want one of the posters? please let us know and we will mail one out to you.

How things have changed…

In 1991 Park Lane Press operated as a trade printer catering primarily to the local book manufacturers and to other printers who struggled to achieve the quality their clients required. We out-sourced the film and plate making and all of our finishing; it was how many printers operated in those days.

We used three lithographic presses, a guillotine and a fork lift truck, a total of five pieces of equipment. It wasn’t easy but so simple back then when clients just wanted leaflets and brochures. We didn’t have mobile phones or even a computer and relied on a fax machine for quotes and orders.

Roll on 30 years and how things have changed. So have we, physically, mentally, and professionally. Since 1991 we have produced 62,532 invoiced jobs to date. That’s a considerable amount of communication and problem solving with very few jobs going wrong – I know that’s hard to believe but it’s true!

The reason I’m being so nostalgic is that we are about to buy another price of equipment next week – a paper banding machine. Not the biggest investment but an important part of the change to our industry. Our clients now prefer belly band finished goods, rather than shrink wrapping.

This got me thinking about the amount of machinery we have at the factory now that we are a “one stop shop”, basically we do it all. On a walk around the factory I counted dozens of machines, some large and some small. I’m sure this is replicated around the country in one form or another, but as they say it’s not what you have it’s the way that you use it, and I’m proud to say we know how to use it!

We are no longer a trade printer but a full service provider, handling variable data, online stock control, pick and pack, fulfilment, distribution and logistics, and the usual weird and wonderful jobs, always finding solutions to clients’ individual requirements and taking their hassle away, currently 62532 times!

HUGE thanks to you and the PLP team! DH

Client thrilled with book. 86 yrs and it rounds off career and explains his work. Also, I got to see the delivery man (and so much more) Tim Bacon. Everybody happy. Bridget L

The brochures arrived and look wonderful. Thanks a lot for your work. Nick W

I’m currently up in very sunny Scotland for the distillery launch. Everything was delivered on time and everyone is really happy with all the print work, so thanks to you and your team for your help, much appreciated. Paul S

Its my first day back in the office and the Impact Reports were here waiting for me. Beautifully printed – everyone loves them and the environmental credentials of the job too. Susie W