Park Lane are currently installing its newest piece of equipment, the new Indigo 7900 digital press. This press will complement our existing plant list which delivers exceptional quality for all jobs – big or small. Our aim is to to provide a short run alternative to waterless litho with a no compromise in the quality of the print. The indigo prints on a wide range of materials as well as printing white, fluorescent colours, as well as the normal Pantone mixes. The machine is a carbon neutral product during its manufacture, and an environmentally friendly option.

See below for a brief video of the engineers at work!

I have just received the copies of Upbeat, they look great! Lucy.C

Just to let you know the leaflets arrived this end and they look great! Caroline.D

Thanks for letting me know. Yes, we received the booklet this morning thank you. it looks fab! Corrina.M.

Many thanks once again for stepping in with the annual reports job for us. We have received them and they look (and smell) great! I love the smell of freshly printed reports for some reason! Alex.W

Just a quick note to say thank you for the leaflets. Your driver was extremely helpful too. Dagmar.S

All has gone down well over the past 12 months, so thanks to all at PLP Phil .R

Thank you so much for my invites – I love them! And thank you so much for folding the outers for me 🙂 that’s saved me a lot of time! I really appreciate it, it’s really kind of you. Eloise.L

By the way the Academy brochure you did for me went down really well. Dan.C

The flyers look amazing, thank you so much for all your hard work on it and the quick turnaround.Nat.G

The days have long gone where printers create film and then expose the image onto plates using a print down frame. Making plates for the press is now completely automated. Once a customer approves their Epson proofs the files are sent to the plate processor where a set of lasers fire the image into the surface of the waterless plate creating holes in the silicone coating . It is then developed in water with fine brushes, which washes any debris from the image surface and is then stacked in sets at the end of the machine.

This continual process means that we use a considerable amount of water during the developing stage. We harvest the water from the waste pipe which leads into two large tanks which are located in the room above the toilets, we then use the water to flush our toilets, and general cleaning. Good for the water bill, great for the environment.

Many thanks for the fabulous stationery. We are delighted as usual. Thank you also for the care and attentive service that Park Lane deliver! Hopefully we will giving away lots of the delicious new business cards at the Listed Property Show this weekend. Wendy T.

Yes, they’re all here and look great Jess P.

Thank you so much for the boards, they are perfect. Paula P.

Great, thanks Marc – I’ve had delivery of the file copies this morning. They look great 🙂 Gemma B.

Yep we’ve got them, they look fantastic Chris B.

Thanks for your help with the reports for our House of Commons event! Katy B.

Got our catalogues – everyone is happy. Thanks for doing a good job! Phil F.

Thank you the cards have arrived safely and are looking great Ute D.

I love green technology that continues to pay you back! We purchased this Voltage Power Optimiser around 10 years ago. This is an electrical energy saving device which is installed in series with the main electricity supply to provide a reduced supply voltage to our site equipment. It saves in the region of 12% p.a. on our electric bill which in turn more than offsets the extra cost for the 100% renewable electricity we use in the business.

Accurately mixing an ink to a specific pantone colour is certainly an art. In this case we are mixing pantone 375 a green. As you can see blue and yellow weighed to the correct proportions should hit the colour correctly, but at Park Lane we also add other colours or additives to make it print better or improve the match to the pantone book. In this case we have added opaque white which produces a better lay down of solid ink. For 25 years we have been mixing inks and have a huge database of formulas, its the extra touches that make the difference, a bit like baking!

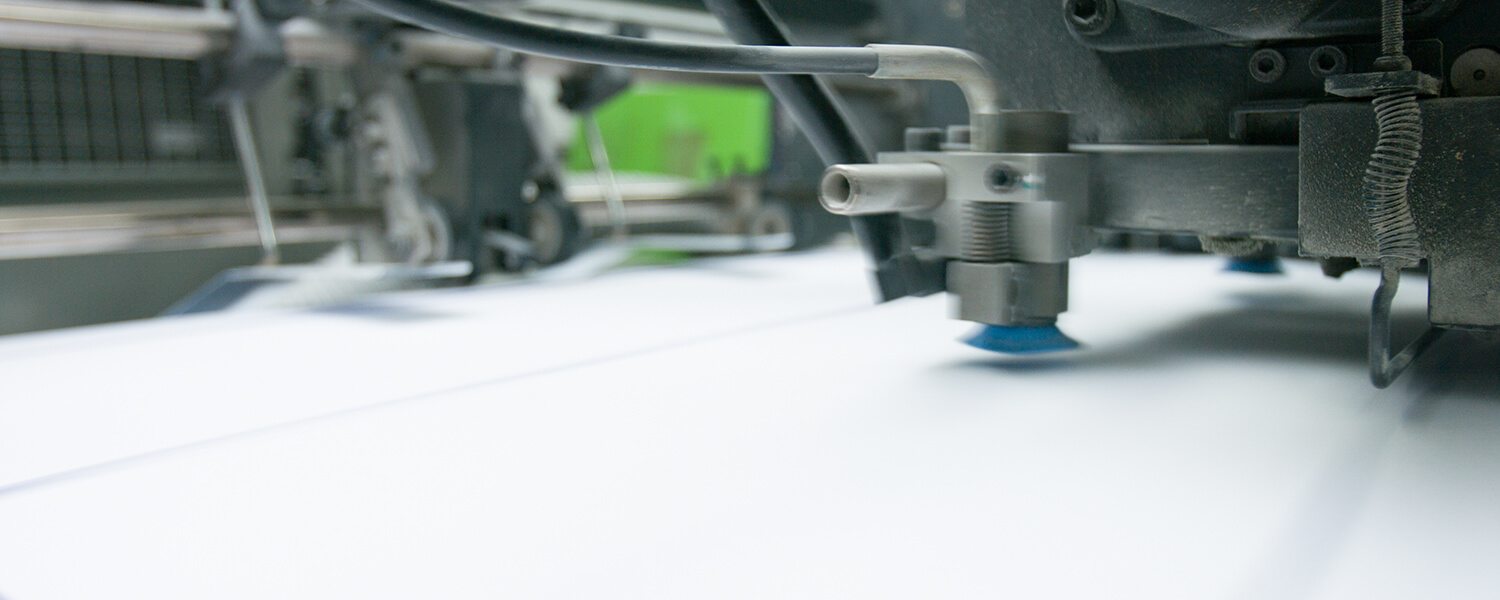

Printing using the waterless process requires the printing press to be maintained to the highest of standards, in order that it can be operated to an expected quality and consistency, which is then translated onto the printed sheet. Today new rollers have been installed in the yellow unit, and the unit is in its final stages of re-calibration.

The ink film thickness on the duct roller has to be set at its minimum of 6 microns. This little gadget (in the image) reads the thickness to ensure that the ink applied to the new rollers is accurate.

It is imperative that this measurement is correct to ensure that the printed sheet matches to the Epson proofs quickly, as any variation which adds time and therefore loses efficiencies in the production process.

Other factors that may impact the thickness of the ink film may include air temperature. If the pressroom is cold the ink will become stiffer and less mobile. Air conditioning within the factory provides a consistent working environment, to eliminate these types of variations.

This is a very small part of the maintenance required to ensure that the manufacturing process limits any possible defects. This helps to provide the exceptional quality we work towards – every time.