Just to say we have the cards and they look great Lynsey.S

They arrived first thing Paul and I’m delighted with them. Thank you Lexy. E.

Apologies for not getting in touch sooner I’ve been away from the office since yesterday but I’d like to offer a belated HUGE THANKS from us all for turning around our print job for our last set of brochures – they looked fantastic and everyone was really happy with the result! Kate.S

Looks good. Thanks for the speedy turnaround. Phil.H

We have received the brochures and they look great. Top quality work, as always.Many thanks for all your help and support on behalf of all the team. Much appreciated. Special thanks to Lee for his great work on pre-press and also on the corrections. Tom.D

The days have long gone where printers create film and then expose the image onto plates using a print down frame. Making plates for the press is now completely automated. Once a customer approves their Epson proofs the files are sent to the plate processor where a set of lasers fire the image into the surface of the waterless plate creating holes in the silicone coating . It is then developed in water with fine brushes, which washes any debris from the image surface and is then stacked in sets at the end of the machine.

This continual process means that we use a considerable amount of water during the developing stage. We harvest the water from the waste pipe which leads into two large tanks which are located in the room above the toilets, we then use the water to flush our toilets, and general cleaning. Good for the water bill, great for the environment.

Printing using the waterless process requires the printing press to be maintained to the highest of standards, in order that it can be operated to an expected quality and consistency, which is then translated onto the printed sheet. Today new rollers have been installed in the yellow unit, and the unit is in its final stages of re-calibration.

The ink film thickness on the duct roller has to be set at its minimum of 6 microns. This little gadget (in the image) reads the thickness to ensure that the ink applied to the new rollers is accurate.

It is imperative that this measurement is correct to ensure that the printed sheet matches to the Epson proofs quickly, as any variation which adds time and therefore loses efficiencies in the production process.

Other factors that may impact the thickness of the ink film may include air temperature. If the pressroom is cold the ink will become stiffer and less mobile. Air conditioning within the factory provides a consistent working environment, to eliminate these types of variations.

This is a very small part of the maintenance required to ensure that the manufacturing process limits any possible defects. This helps to provide the exceptional quality we work towards – every time.

Just wanted to say a huge thank you for the prospectuses. They arrived safe and sound earlier today and we’re all very impressed with them. I’ve already taken a few copies to show my mum – a true sign of quality! 🙂 – Ben R.

Very happy client. Fantastic work thank you very much – Scott G.

Postcards and wallets arrived yesterday, really delighted with them! Park Lane have been great. – Kerrie B.

The calendars have arrived and look great. Many thanks indeed for such a prompt and efficient service. – Phil H.

Thank you for your support of this event, it is very much appreciated – Saltford School

Thanks – they’re all with us now and looking great – Selma W.

Many thanks for the brilliantly printed books and the great service, I have often been disappointed when I’ve seen my work in print but not this time.– Jane B.

The Unlimited publication looks amazing! We’re so pleased with it. Thanks for all your hard work in getting it to us on time, at a high quality, and with patience. – Jennifer T.

We’re delighted to announce that we’ve WON the award for Environmental Business of the Year at The Bath Chronicle Business Awards.Park Lane Press has had in place an environmental management system since 2002. The award went to the which has shown outstanding commitment to manage the environmental impact of its business or has developed its own business in the field of managing the environmental impact of other businesses or the wider community.

Our entry this year recognised the following changes we’ve implemented this year:-

• The installation of an LED lighting system throughout the factory and offices.

• The saving on the use of paper in the make-ready of the printing presses by reducing the overs.

• The purchase of large quantities of paper directly from the mill instead of through merchants therefore reducing the transportation of the goods and merchants handling costs.

The green measures we already had in place include:-

• Environmental accreditation’s EMAS and ISO 14001 & 9001.

• Harvesting waste water from our plate processor in order to flush the toilets.

• All the electric used within the business is generated from renewable sources.

• Our inks are vegetable based.

• 97% of our waste is recycled.

• Power optimisation unit, maintaining a constant voltage to the machinery.

• Paper usage recycled or FSC accredited as a minimum.

These accomplishments take the continued efforts of all our staff, and the awards reflect their commitment to the environment.

The Bath Chronicle Business Awards celebrate business success across the city and surrounding areas. The awards are now in their 6th year and have seen a wide range of businesses winning awards in that time. We’re very pleased and proud to have been chosen for this award.

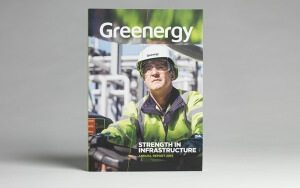

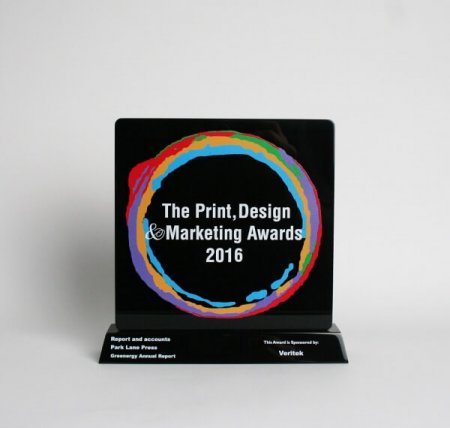

On the 30th June 2016 I attended the Whitmar Publications ‘Print, Design & Marketing Awards 2016’ held aboard the Silver Sturgeon on the River Thames. Park Lane were nominated for best website www.parklanepress.co.uk, created by one of our clients Lionhouse Creative.

The second nomination was for the Report and Accounts category, which we won. The judges said: An outstanding piece of print that is clear, precise and full of colour. Excellent finishing and binding combined with exceptional quality.

The award was for the production of the Greenergy Annual Report designed by MrB and Friends. We are especially pleased as it was produced on an uncoated stock, and printed waterless in 6 colours with PUR binding. The 132 page A4 portrait report used no fancy papers, or extra embellishments.

This kind of job is typical of what goes through Park Lane Press on a weekly basis, simple jobs can look amazing when done well. For us I think it is (like a good decorator will tell you) all in the preparation. A careful analysis of every job to ensure the paper, job design and finishing choices match the expectations of the client, this is key.